Flange Insulation Kits

• Designed to minimize the effects of electro chemical corrosion.

• Used to isolate sections of pipe works.

• Made from material with high dielectric strength.

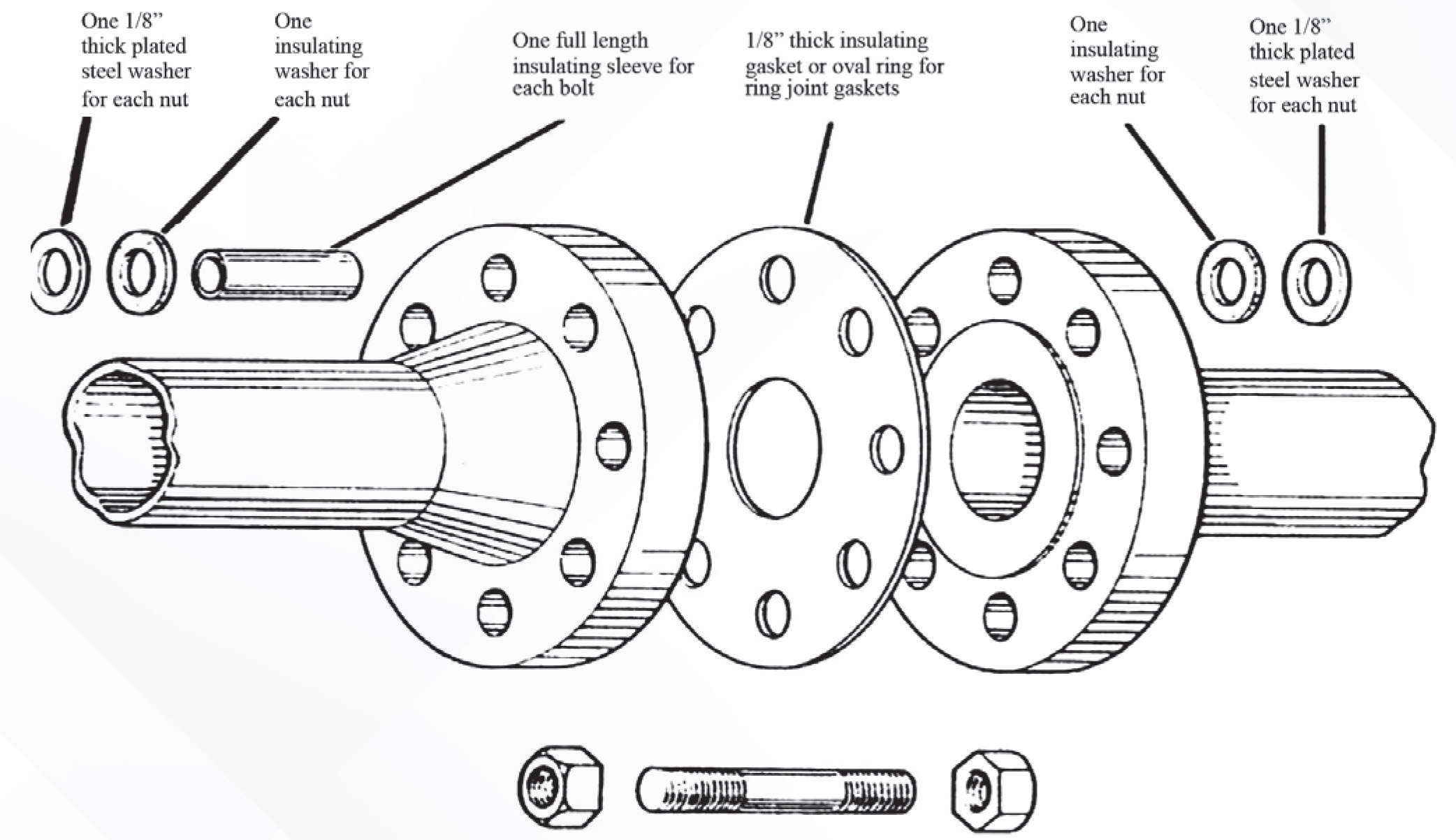

• Each set composes of:

• One central flat or oval section gasket.

• One insulating sleeve per bolt.

• Two insulation & two plated steel washers per bolt.

• Manufactured to suit flanged joints to ANSI, BS, DIN & customer designs.

• Individually packed & clearly labeled with the flange rating, size, and type & material combination.

• Extremely high reliability sealing and insulating solution for all critical services.

• Superior sealing solution for low pressure.

• Extremely high reliability sealing and insulation solution for all aggressive chemical & critical services.

• Applicable for use with portable and drinking water applications.

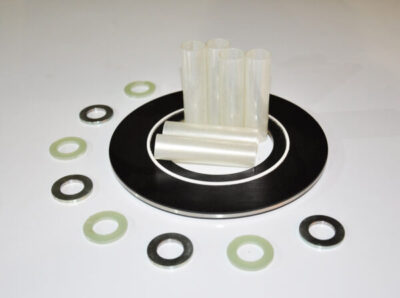

Typical Example Of Insulation Components

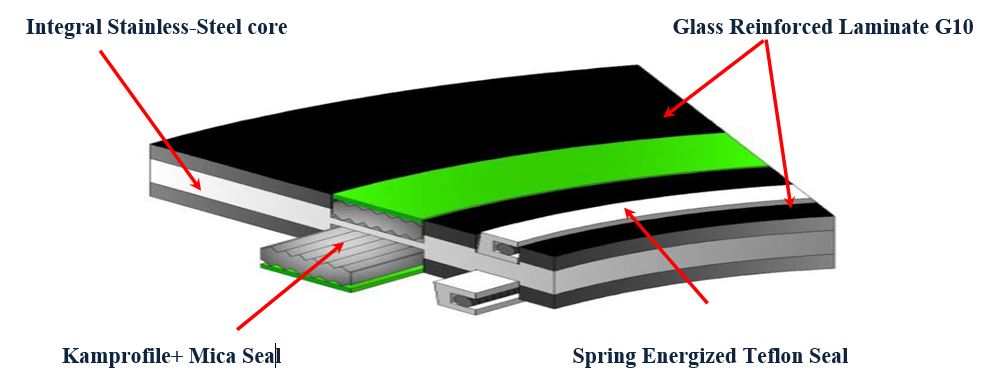

Flange insulation kit SBV-12

consist of central gasket of SS core with G10/G11 retainer with Teflon

seal, used for high pressure and critical application to seal flanges and control stray electric currents in piping at oil, gas, water, refinery, and chemical plants, to increase the effectiveness of cathodic protection systems.

General Properties and application

• Extremely high reliability sealing and insulating solution for all aggressive chemical & critical services.

• Formation of isolation bridge for better electrical resistance

• The best for use in high chloride applications that could cause corrosion cracking with stainless steel core

• Designed to withstand corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

• Avoid the need of exotic metal core because it breaks the metal to metal ion flow hence minimize the extra expanse.

• Pressure activated seals provides high confidence sealing and eliminates costly leaks.

• Available with G11 retainer for up to 180 °C

• Can seal mismatch RTJ Flange with Raised Face Flanges.

With the consideration of economic and environmental protection, to prevent leakage of carrier pipelines has become more urgent than any time before. Flange is always the most common problem area; therefore, properly sealing the flanges has been the key point to solve pipeline leakage. Meanwhile, the flanges also need to be catholically isolated to prevent stray currents from causing corrosion and damage to pipelines.

With the consideration of economic and environmental protection, to prevent leakage of carrier pipelines has become more urgent than any time before. Flange is always the most common problem area; therefore, properly sealing the flanges has been the key point to solve pipeline leakage. Meanwhile, the flanges also need to be catholically isolated to prevent stray currents from causing corrosion and damage to pipelines.

Saudi Bisan can offer a series of materials and types of flange insulation gasket kits, to solve the sealing and insulating problems of flanges, and to control losses due to corrosion and leakage of pipelines. They are widely used to seal flanges and control stray electric currents in piping at oil, gas, water, refinery, and chemical plants, to increase the effectiveness of cathodic protection systems.

Main feature of Insulation kit:

- Extremely high reliability sealing and insulating solution for all critical services.

- Seals and insulates at all pressures up to ANSI 2500# and API 15000#.

- Unique stainless steel core bonded with high strength insulating laminate withstands severe service conditions including large bending moments, vibration, temperature and pressure cycling.

- Designed to withstand corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

- Outstanding insulation properties for cathodic protection.

- Pressure activated seals provides high confidence sealing and eliminates costly leaks.

- Gasket is sized to the flange bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections.

- Mitigates galvanic corrosion in dissimilar metal flanges.

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others).

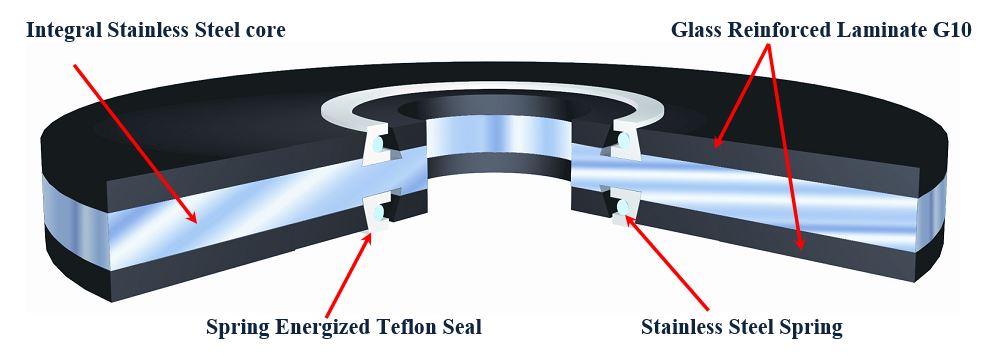

SBV-12 seal insulating gasket utilizes a stainless-steel core boned with high strength insulating laminate G10 or G11, which not only maintains the high strength of stainless steel, but also reaches an excellent insulation. It consists of a spring-energized Teflon seal which provides high confidence sealing and eliminates costly leaks. And the seal groove is cut into the stainless-steel core, which can avoid leakage through the interval of two materials.

SBV-12 seal insulating gasket is designed to seal and insulate for very critical services. It can seal and insulate raised face flanges, full face flanges, and ring joint flanges at all pressures up to ANSI 2500# and API 15000#. While 316 grade of stainless steel is most commonly required as a core material, we can also offer more exotic materials such as Super Duplex, Hastelloy and Inconel

Sealing Gasket Retainer physical properties:

| Unit | ASTM | G-10 Epoxy Glass | G-11 Epoxy Glass | |

| Di-electric Strength | Volts/Mill (Short Time) | D149 | 650 | 550 |

| Compressive Strength | Psi | D695 | 65,000 | 50,000 |

| Water absorption | % | D229 | 0.05 | 0.04 |

| Tensile Strength | Psi | D638 | 50,000 | 43,000 |

| Flexural Strength | Psi | D790 | 65,000 | 50,000 |

| Shear Strength | Psi | D732 | 22,000 | 20,000 |

| Insulation resistance | Meg Ohms | D257 | 200,000 | 200,000 |

| Impact strength | Ft-Lb/Inch | D256 | 14 | 12 |

| Operating Temperature | °C | -65 to +150 | -65 to +180 |

| Core Material |

| Stainless Steel 316L, 316, 304, 321, 310, 347 |

| Monel 400. |

| Inconel 600, 625. |

| Nickel 200. |

| Titanium, Hastelloy/ Inconel 800, 825. |

| Gasket Retainer material |

| G10 |

| G11 |

| Sleeve material |

| Mylar |

| Nomax |

| G10 |

| G11 |

| G7, Phenolic |

| Washer material |

| G10 |

| G11 |

| G3 |

| G7 |

| PHENOLIC |

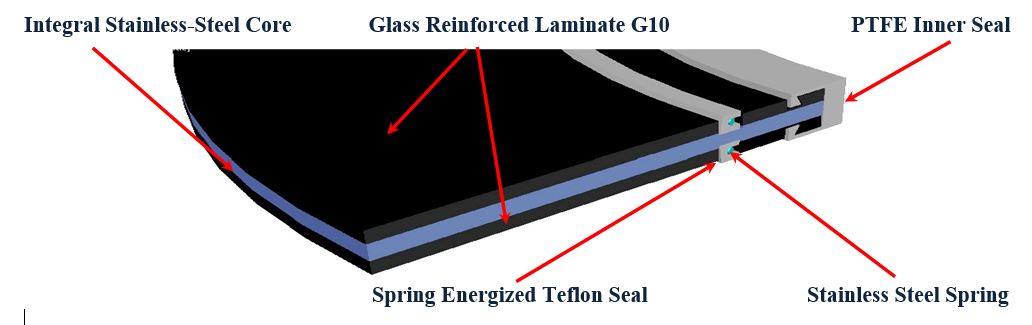

With the consideration of economic and environmental protection, to prevent leakage of carrier pipelines has become more urgent than any time before. Saudi Bisan offer a series of materials and types of flange insulation gasket kits, to solve the sealing and insulating problems of flanges, further challenge by the market requirements to provide solutions for electrical isolation in conductive environments as well as chemical resistance to aggressive media.

We provide solution with use of inner PTFE seal to protect the gasket from the aggressive chemical with double lock system created by us, this seal will isolate the steel core of the gasket from direct contact with media especially if it contains conduction particles forming a conductive bridge between flange and steel core.

Main feature of Insulation kit:

- Extremely high reliability sealing and insulating solution for all critical services.

- Seals and insulates at all pressures up to ANSI 2500# and API 15000#.

- Unique stainless steel core bonded with high strength insulating laminate withstands severe service conditions including large bending moments, vibration, temperature and pressure cycling.

- Designed to withstand corrosive environments, including high concentrations of CO2, H2S, produced water, etc.

- Outstanding insulation properties for cathodic protection.

- Pressure activated seals provides high confidence sealing and eliminates costly leaks.

- Gasket is sized to the flange bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections.

- Mitigates galvanic corrosion in dissimilar metal flanges.

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others).

Sealing Gasket Retainer physical properties:

Unit | ASTM | G-10 Epoxy Glass | G-11 Epoxy Glass | |

Di-electric Strength | Volts/Mill (Short Time) | D149 | 650 | 550 |

Compressive Strength | Psi | D695 | 65,000 | 50,000 |

Water absorption | % | D229 | 0.05 | 0.04 |

Tensile Strength | Psi | D638 | 50,000 | 43,000 |

Flexural Strength | Psi | D790 | 65,000 | 50,000 |

Shear Strength | Psi | D732 | 22,000 | 20,000 |

Insulation resistance | Meg Ohms | D257 | 200,000 | 200,000 |

Impact strength | Ft-Lb/Inch | D256 | 14 | 12 |

Operating Temperature | °C |

| -65 to +150 | -65 to +180 |

As well as manufacturing the gasket, we also provide the following isolating components to suite all flange type, pressure rating and temperature; –

- Isolating bolt sleeve which could be maylar, phenolic, Nomax, G7, G10 and G11

- Isolating washers could be phenolic, G3, G7, G10 and G11

- Steel plated washers or stainless-steel washers

The demand of the SBV-12-FS was driven by the demands of market requirements who needed to electrically isolate their flanges but worried about the performance of non-metallic components in the event of a fire. This was especially a concern in the offshore market where the consequences of a fire on platforms are very hazardous and costly also in piping and LNG applications, where the risk of a fire would greatly threaten life and property, drove the need for an electrical isolation seal that is fire safe per API 6FB.

Saudi Bisan can offer a series of materials and types of flange insulation gasket kits, to solve the sealing and insulating problems of flanges, and to control losses due to corrosion and leakage of pipelines. They are widely used to seal flanges and control stray electric currents in piping at oil, gas, water, refinery, and chemical plants, to increase the effectiveness of cathodic protection systems.

Main feature of Insulation kit:

- Extremely high reliability sealing and insulating solution for all critical services.

- Seals and insulates at all pressures up to ANSI 2500# and API 15000#.

- Unique design including Viton O-ring.

- Provide complete electrical isolation

- Secondary seal work on dual purpose for fire safe and back up seal system

- Approved for API 6FB, third addition test

- Gasket is sized to the flange bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections.

- Mitigates galvanic corrosion in dissimilar metal flanges.

- Available to match any flange specification (ANSI, API, BS, DIN, AS, others).

- Can seal mismatch RTJ Flange with Raised Face Flanges.

- Can work for higher temperature up to 200 °C by use of G11 material.

SBV-12 seal insulating gasket is designed to seal and insulate for very critical services. It can seal and insulate raised face flanges, full face flanges, and ring joint flanges at all pressures up to ANSI 2500# and API 15000#. While 316 grade of stainless steel is most commonly required as a core material, we can also offer more exotic materials such as Super Duplex, Hastelloy and Inconel

Sealing Gasket Retainer physical properties:

Unit | ASTM | G-10 Epoxy Glass | G-11 Epoxy Glass | |

Di-electric Strength | Volts/Mill (Short Time) | D149 | 700 | 550 |

Compressive Strength | Psi | D695 | 65,000 | 50,000 |

Water absorption | % | D229 | 0.05 | 0.04 |

Tensile Strength | Psi | D638 | 50,000 | 43,000 |

Flexural Strength | Psi | D790 | 65,000 | 50,000 |

Shear Strength | Psi | D732 | 22,000 | 20,000 |

Insulation resistance | Meg Ohms | D257 | 200,000 | 200,000 |

Impact strength | Ft-Lb/Inch | D256 | 14 | 12 |

Operating Temperature | °C |

| -65 to +150 | -65 to +200 |

Flange Insulation Kit SBG-11 Seal

With the consideration of economic and environmental protection, to prevent leakage of carrier pipelines has become more urgent than any time before. Flange is always the most common problem area; therefore, properly sealing the flanges has been the key point to solve pipeline leakage. Meanwhile, the flanges also need to be cathodically isolated to prevent stray currents from causing corrosion; therefore, flange insulation kit is used to prevent the process of galvanic corrosion by ensuring the interruption of electrical continuity between adjacent flanges and isolating each component without interfering with the proper tightening of the flange.

With the consideration of economic and environmental protection, to prevent leakage of carrier pipelines has become more urgent than any time before. Flange is always the most common problem area; therefore, properly sealing the flanges has been the key point to solve pipeline leakage. Meanwhile, the flanges also need to be cathodically isolated to prevent stray currents from causing corrosion; therefore, flange insulation kit is used to prevent the process of galvanic corrosion by ensuring the interruption of electrical continuity between adjacent flanges and isolating each component without interfering with the proper tightening of the flange.

Seal gasket use G10 or G11 epoxy glass as retainer, and use two o-ring seal elements overlapping and offsetting into two unique seal grooves, thus, the seal elements can be sealed without outside pressure. This can eliminate potential leak in the laminate material, and increases the choice of seal elements. This kind of sealing gasket can use Viton, EPDM, neoprene or any type of rubber as seal elements.

Seal gaskets use also a rectangular sealing element enclosed into a unique groove to seal and isolate all types of flanges. This kind of gasket can provide theoretical near zero “m” and “y” factors resulting in effecting a positive seal without excessive bolt loads required with flat gaskets. Materials such as Teflon and viton also can be used as the sealing element, which increases the choice of material.

Seal gasket use G10 or G11 epoxy glass as retainer, and use two sophisticated Spring-Energized Teflon lip seal element overlapping and offsetting into two unique seal grooves, thus, the seal elements can be sealed without outside pressure. This can eliminate potential leak in the laminate material, the resilience of Teflon and increase the whole gasket’s sealing performance.

Camprofile gasket use G10 or G11 epoxy glass as retainer, and use two layer of multi directional expanded PTFE layer as a sealing element can be sealed with low bolt load required with flat gasket, we can use expanded PTFE and Viton rubber which increase the choice of sealing material. Camprofile gasket can be reused by changing the sealing layer

SBG-11 sealing gaskets are widely used for low and medium pressure, suitable for use in raised-face and flat-face flanges in ANSI class 150 and 300 service or equivalent to fit any flange diameter.

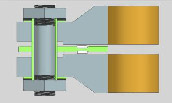

Before tightening after tightening

Main Feature:

- Superior sealing solution for low pressure.

- Used for raised face I.B.C and full face flange.

- Low compressive load and clamping.

- Outstanding insulation properties for cathodic protection.

- Gasket is sized to the flange bore to protect flange faces from media-induced corrosion and flow-induced erosion. Prevents turbulent flow at flanged connections.

- Mitigates galvanic corrosion in dissimilar metal flanges.

- Available with variety of elastomeric seals.

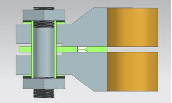

SBG-10 Seal Insulation Sets

Insulation sets are used to limit corrosion in pipeline systems. Where dissimilar metals are present, the sets remove the possibility of the system acting as a galvanic cell and reduce the risk of

Insulation sets are used to limit corrosion in pipeline systems. Where dissimilar metals are present, the sets remove the possibility of the system acting as a galvanic cell and reduce the risk of

galvanic corrosion of the pipe work.

Insulation sets are also used to isolate cathodically protected piping systems where they prevent the

flow of electro-static charge

Componenet |

| 1 | 2 | 3 | 4 | 5 | 6 |

Dielectric strength | V/mm | 500 | 200 | 400 | 140 | 4000 | 1500 |

Compressive strength | N/mm2 | 270 | 270 |

|

|

|

|

Felxural Strength | N/mm2 | 155 | 155 |

|

|

|

|

Water Absorption | % | 1.6 | 1 | 0.01 | 1 | 0.8 | 10.6 |

Maximum Tempreture | C | 107 | 107 | 66 | 107 | 180 | 350 |

Each flange insulation set

comprises one central flat or oval section gasket, one insulation sleeve per bolt and two insulating and two plated steel washers per

bolt. The sets are individually packed and clearly labelled with the flange rating, size, type

and material combination.

This kind of material will be used mainly for unitlites and low pressure application for class rating 150 and 300 only

This kind of material could be used for utility applications and for portable water application gasket should be approved by WRC ( NOVAPRESS 260).

1 | Type E & F Central Gasket | Neoprene Faced phenolic |

2 | Insulating Washer, Type D Gasket | Reinforced phenolic |

3 | Insulating Sleeve | Polyethylene |

4 | Insulating Sleeve | Phenolic |

5 | Insulating Sleeve | Mylar |

6 | Type E & F Central Gasket | NOVAPRESS 260 |