Non- Metallic Gaskets

Graphite Gaskets

Material Types

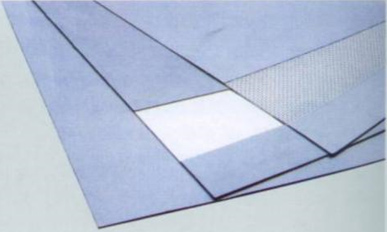

- Pure Exfoliated (Expanded) graphite With Anti Stick Finish.

- Pure Exfoliated (Expanded) Graphite with SS Tanged Reinforcement & Anti Stick Finish.

- Pure Exfoliated (Expanded) Graphite with SS Foil Reinforcement & Anti Stick Finish.

- Pure Exfoliated ( Expanded) Graphite with SS wire mesh.

General Properties

• Outstanding resistance to high and low temperatures.

• Chemically resistant to virtually all media.

• High compressibility.

• Low creep under temperature or pressure.

• Seals gases and liquids effectively at low bolt loadings

• Unlimited storage life.

• High and low temperatures.

• Aggressive media.

• Low bolt loads.

• Sealing of damaged flange surfaces.

• Hot oil equipment.

• Liquid gas plants.

• Heat exchangers.

• Glass, enamel flanges.

• Nuclear power plants.

• Cylinder head and manifold gaskets for engines and compressors.

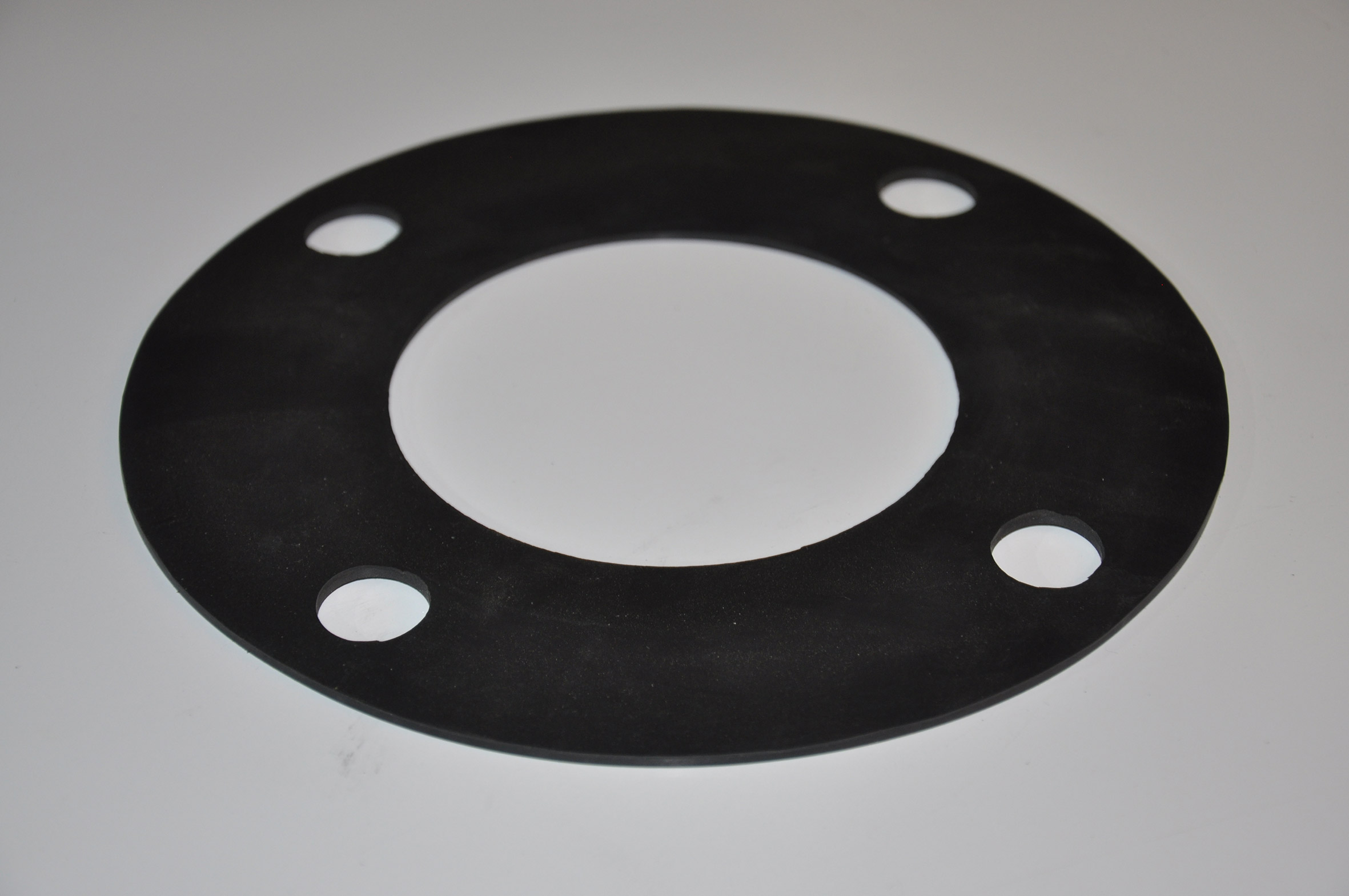

Rubber Gaskets

Rubber and paper based gasket materials offer a low cost sealing solution for applications where the additional strength offered by fiber reinforcement such as aramid, glass or carbon is not a requirement. Rubber and paper based materials are often used in low temperature and pressure application.

CR or chloroprene is a homoploymer of chloroprene or chlorobutidine. It has excellent mechanical and

abrasion properties. It displays good resistance to heat, ozone and weathering and also gives good adhesion

to metal. Recommended operating temperature range from -40º C to +110º C. it has good resistance to

organic hydrocarbons

EPDM or Ethylene Propylene Diene Monomer. It is highly recommended for outdoor uses as it’s extremely

resistance to oxidation, U.V, Rays and ozone. However EPDM does not have good oil resistance or adhesion

properties. It is resistance to many chemical and solvents and shows good resistance to may corrosive

chemicals. Recommended operating temperature – 40º C to +140º C

NR or Natural Rubber polyisoprene is derived from latex liquid extracted from rubber tress. It has excellent

mechanical properties, low compression set and high resilience; it also has excellent dynamic and rebound

properties. It has good resistance to acids, alkalis and salts. It’s not recommended to use with oil and

hydrocarbons. Recommended operating temperature -40º C to 90º C

Fluoro Elastomer or viton is based on hexafluoropropylene vinylidene fluoride. High temperature rubber which

exhibits a wide range of chemical resistance. Extremely resistance to the effects of oxygen and ozone. Retains

excellent mechanical properties even when subjected to high temperature for long periods of time. Used for

many acids and alkalis, aliphatic hydrocarbons, oils and ozone chlorine. Recommended operating temperature

-20ºC to 200ºC.

Haypalon is excellent resistance to ozone and good resistance to mineral oils, weathering and acids.

Processes excellent resistance to ozone and good resistance to flame, mineral oils, heat, weather and acid,

making it ideal for use outdoors or near sparking electrical equipment. Used for acids, oils and non aromatic

benzenes. Recommended operating temperature -20ºC to 120ºC

Nitrile or acrylonitrile butadiene. It has good general resistance to oil along with good mechanical properties

especially tensile strength, flexing, compression set and impermeability to gases. It also displays a good

resistance to inorganic chemical products except antioxidant agents and chlorine. It gives satisfactory

resistance to general hydrocarbons. Recommended operating temperature -40ºC to 100ºC.

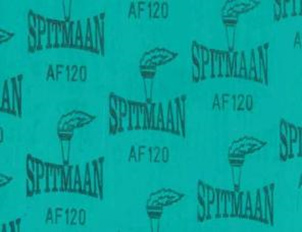

Non-Asbestos Gaskets

Material: medium quality compressed fiber jointing based on aramide fiber, mineral and synthetic fiber with NBR binder.

Color: Green both side

General Properties

General purpose, include oils fuels, low pressure steam, water and gases, specific oil resistance.

Applications

Medium loading, excellent resistance to oils, hot water, gases, hydrocarbon and many chemicals.

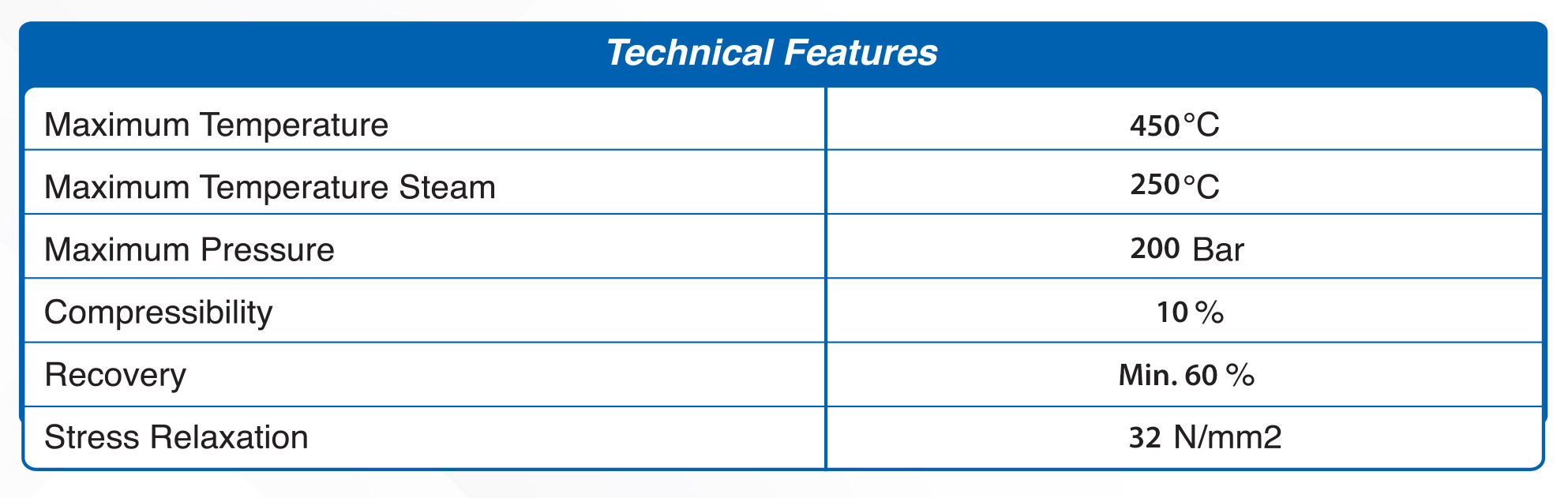

Technical Features

Material: medium A premium grade jointing sheet based on special synthetic Aramid fibers bonded with nitrile rubber binder elastomer, To BS 7531 Grade X. Color : Gray both side

General Properties

A universal heavy-duty grade suitable for many industrial sealing applications

Applications

Resistance to hot oils, fuels, hydrocarbons and refrigerants (high service conditions).

Technical Features

Material: Superior performance jointing sheet incorporated a blend of special heat resistant aramid fibers bonded with high quality NBR binder Color: Natural Yellow

General Properties

This primum quality gasket have a properties of General purpose use, Good handling properties, Good residual stress, Low gas leakage rate, comply with BS 7531 Grade x

Applications

Suitable for use with oils, solvent, gases, steam, dilute acid and alkalies

Technical Features

PTFE Gaskets

Polytetrafluoroethylene (PTFE) is almost chemically inert being attacked only under extreme conditions by, for example, molten alkali metals, certain fluorine compounds at elevated temperature and nuclear radiations. In this respect PTFE is very useful as a gasket material, but unfortunately, the material has a tendency to creep under load and has limited use in such applications

General Properties

Applications

– Outstanding chemical resistance.

– Suitable for use with foodstuff and pharmaceutical applications.

– Insoluble in solvents, even at increased temperature.

– Stable to light.

– Does not absorb water.

– Excellent electrical insulating capacity.

– Low thermal conductivity.

– Aggressive or toxic fluids.

– Pharmaceutical industry.

– Food industry.

– Chemical industry.

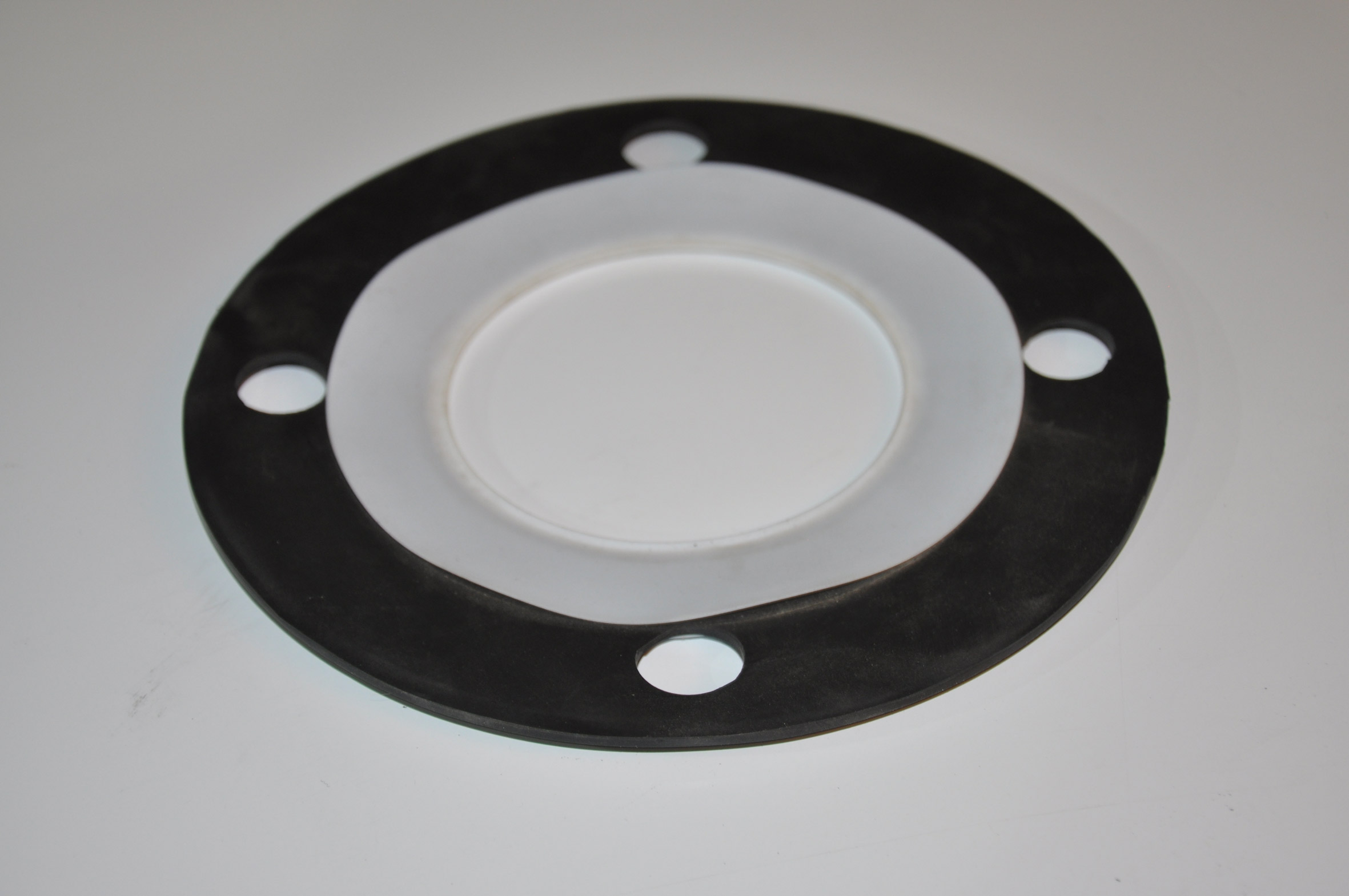

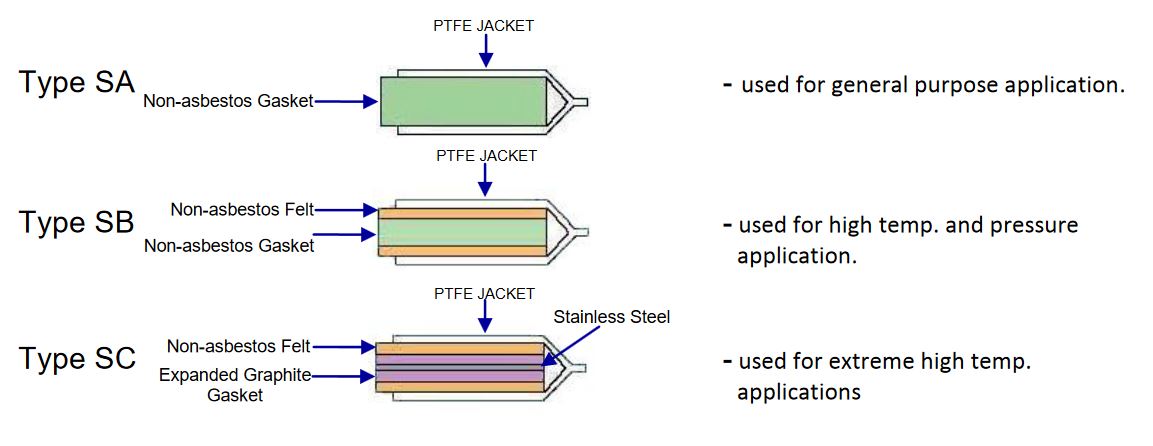

PTFE Envelope Gaskets

We can manufacture PTFE gaskets according to international standards as well as to customer’s requirements. PTFE envelope gaskets comprise a compressed synthetic fibre gasket material insert with a PTFE envelope. The PTFE envelope protects the gasket from chemical attack. The insert provides the strength and resilience needed for demanding sealing operation. PTFE in all its forms is also available filled with various materials, such as glass, graphite, aluminum, carbon and other fibres which further improve the excellent properties of PTFE depending on customer needs.