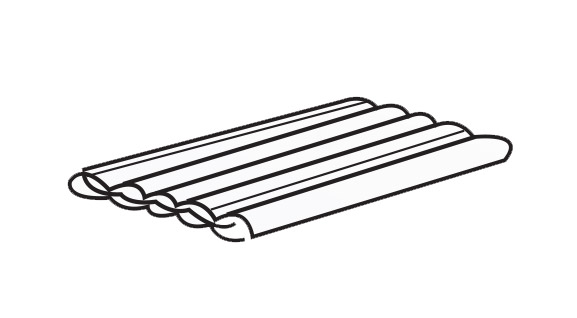

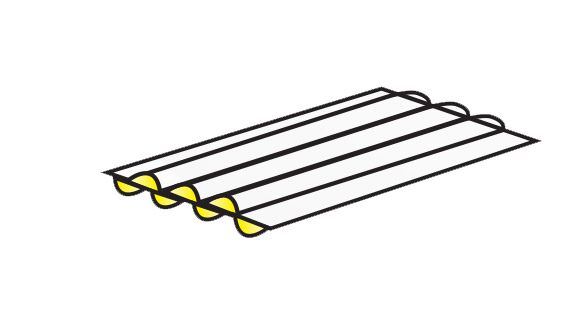

Metal Jacketed Gaskets

Soft Iron, soft steel, stainless steel 304, 321, 316, 410, copper, brass, monel, chrome, aluminum, incoloy,

titanium, Inconel, nickel.

Non asbestos millboard, rubber, PTFE, Graflex exfoliated graphite.

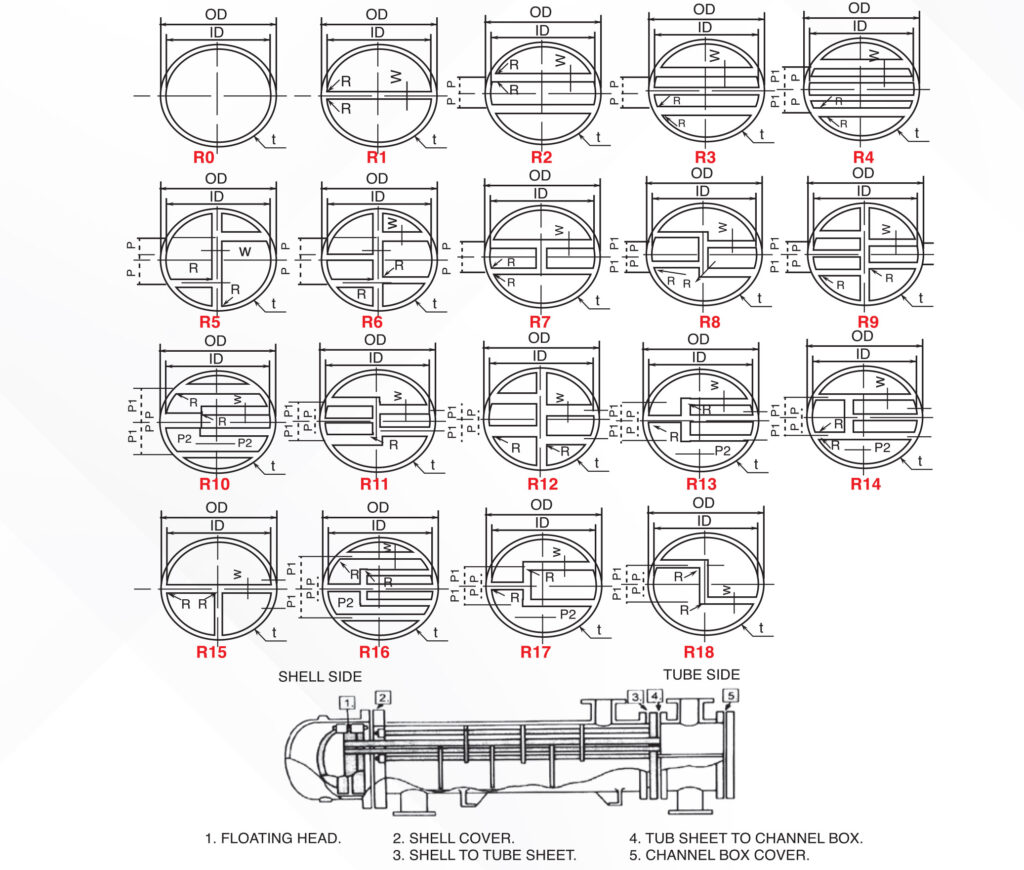

– Outside diameter.

– Bar width size.

– Inside diameter.

– Radius of bar connection

– Shape per standard index.

– Distance from center line of gasket to center line of bars.

– Type number.

– Thickness.

– Material (metal/ filler material

Gasket Shape Index

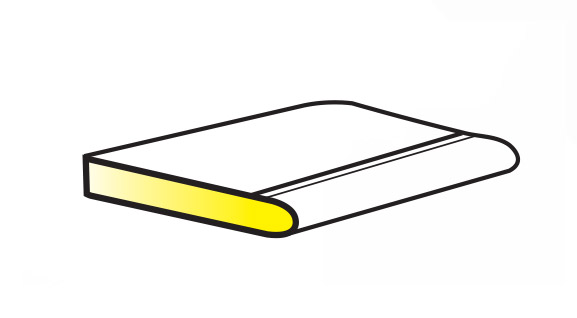

Similar to type 215 used on high temperature pressure applications or

where corrosion problem may exist.

Very seldom used, old design. Used in applications where poor or pitted

flanges exist on one facing.

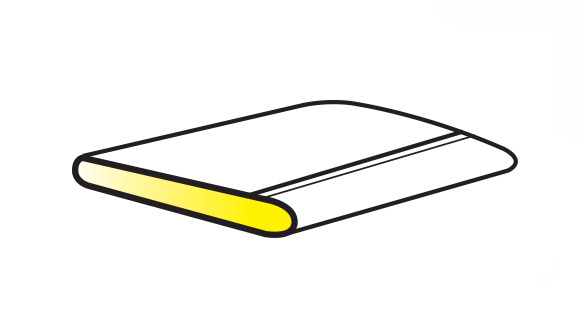

Similar to type 210, less able withstand higher pressure. Used on narrow

flanges where type 100 unsuitable.

Used in narrow flanges, protection of filler calered by casing.

Used mainly in valve applications, small recess gap. Sometimes referred to

as taylor ring.

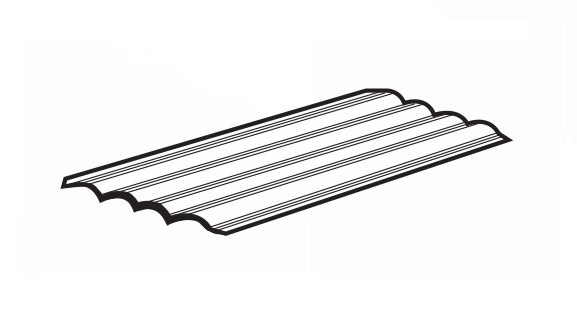

Improvement on type 210. Reduced contact area, enhance compression

characteristics, suitable for uneven flanges.

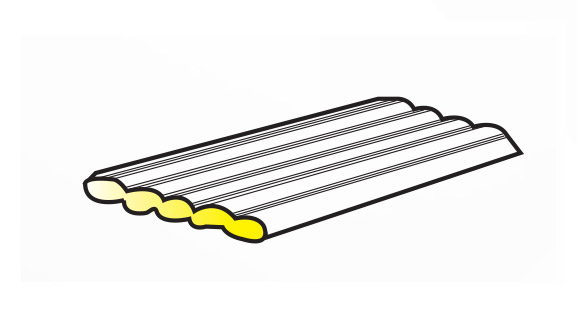

Usually stainless outer casing with soft iron filler ring. Core material

available SS 304, 316L, 321, soft iron, monel, inconel.

Typically used on very poor or pitted flanges, low bolt loading requirement.

Combines flexible graphite with stainless steel core material.